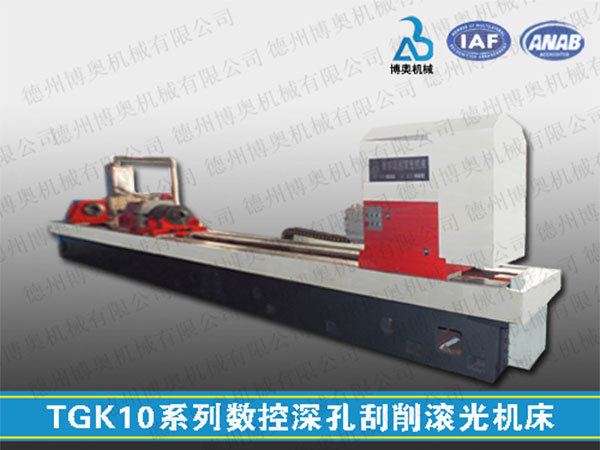

TGK10 series CNC scraping and rolling machine

Category:

Keywords:

TGK10

Hotline:

TGK10 series CNC scraping and rolling machine

TGK series CNC type scraping and rolling machine is a new generation of scraping and rolling machine developed by the company. The machine tool can realize the scraping and rolling process of the workpiece. The main features of the machine tool are high processing efficiency, stable performance, intelligent and simple CNC operating system, overall beautiful, unified and neat appearance, and better anti-oil splash and anti-leakage. environmental protection measures.

The equipment is designed for workpiece fixing and single rotation of the tool, and adopts the combined processing technology of scraping and rolling, which effectively solves the serious deviation of the deep hole roughing of the hot-rolled steel pipe and the poor straightness after the deep hole finishing of the cold-drawn steel pipe, leading the way. Solve major problems in deep hole processing at home and abroad. Mainly used for deep hole boring and rolling combined processing of hydraulic cylinder parts. After rapid scraping and rolling processing, the precision can reach IT7-8 level, the surface roughness can reach Ra0.2-0.4μm, and the processing efficiency is traditional: rough boring → semi-fine boring → floating boring → deep hole rolling process. 10 times, which is 20 times that of the general retort mill. The machine tool is equipped with an automatic tool expansion and contraction control module, and has a dedicated Korean-style pneumatic and German-style hydraulic tool expansion and retraction system. The machining allowance is 0.2-8mm in the diameter direction.

The machining method of the machine tool is: the workpiece is fixed, the tool rotates and feeds through the feed transmission system.

TGK series machine tools are equipped with German SIEMENS 808 numerical control system; the spindle box is driven by an AC variable frequency spindle motor with stepless speed regulation, and the spindle bearing adopts high-precision bearings with high rotation accuracy. The feed box is driven by an AC servo motor with stepless speed regulation; the bed body is made of high-quality cast iron, and the double-flat guide rails ensure the overall rigidity and good guidance of the machine tool, and there are protective structures around it. The machine tool is equipped with automatic chip removal machine, magnetic separator, paper filter, etc., to fully ensure the clean recovery and reuse of coolant. The filtration precision can reach 20 μm.

|

Technical Specifications |

TGK10 |

|

Processing ground diameter range |

φ35-Φ150mm |

|

Machining depth range |

1-12m |

|

Machine guide rail width |

500mm |

|

Spindle center height |

300mm |

|

Spindle speed range, series |

5-1200r/min |

|

Main motor |

30kw |

|

Feed speed range |

5-3000mm/min |

|

Tool feed pallet rapid movement speed |

3/6m/min |

|

Clamping workpiece diameter range |

φ40-Φ150mm |

|

Feed motor |

27Nm |

|

Cooling pump motor |

N=5.5kw |

|

Hydraulic pump motor |

/ |

|

Cooling system rated pressure |

2.5MPa |

|

Cooling system flow |

200L/min, 200L/min |

|

Air pressure |

≥0.4Mpa |

|

CNC system |

SIEMENS808 |

Feedback

Related Products

DEZHOU BOAO MACHINERY CO., LTD.

Add:Jintian Entrepreneurship Center, Tianqu Industrial Park, Decheng District

Tel:86-0534-2429518

Fax:86-0534-2429918

E-mail:dzjichuang@163.com

© 2022 DEZHOU BOAO MACHINERY CO., LTD.