TGK36 series heavy-duty CNC skiving and rolling machine

Category:

Keywords:

TGK36

Hotline:

TGK36 series heavy-duty CNC skiving and rolling machine

TGK36 series heavy-duty CNC scraping and rolling machine tools can adopt the processing method of workpiece rotation, fixed tool and feeding movement. The workpiece can also be fixed, the tool is rotated and the processing method is performed. The machine tool can realize the scraping and rolling of the inner hole of the workpiece, the processing technology is simple (one-time processing and forming), and the processed product has high precision. The main advantages of this machine tool are: high processing efficiency, stable performance, and the efficiency is 5 to 10 times that of traditional deep hole boring machines; high degree of intelligent control, digital control and monitoring of various action instructions of the machine tool, automation of the processing process, simple and convenient Easy to operate.

TGK heavy-duty series machine tools are equipped with Siemens numerical control system; the spindle box is driven by AC variable frequency motor with stepless speed regulation, and the spindle bearing adopts famous brand high-precision bearings with high rotation accuracy. The feed box is driven by an AC servo motor with stepless speed regulation; the feed mechanism is driven by rack and pinion, with good rigidity, which can realize high-precision and stable feeding of the spindle box. The bed body is made of high-quality cast iron, the double rectangular flat guide rails ensure the overall rigidity of the machine tool, and there are protective mechanisms around it. A dedicated hydraulic self-centering fixture ensures the stability of the workpiece during high-speed machining. The machine tool is equipped with automatic chip conveyor, oil temperature cooler and magnetic separator to ensure clean recovery and reuse of coolant.

|

Technical parameters |

TGK36 |

|

Machining diameter range |

Φ60-Φ360mm |

|

Machining depth range |

1-12m |

|

Machine guide rail width |

650mm |

|

Spindle center height |

450mm |

|

Spindle speed range, series |

60~1000r/min (4 files stepless) |

|

Main motor |

60kW/75KW (frequency conversion) |

|

Feed speed range |

5-3000mm/min (stepless) |

|

Tool feed pallet rapid movement speed |

3/6m/min |

|

Clamping workpiece diameter range |

Φ120mm-Φ450mm |

|

Feed motor |

48Nm |

|

Cooling pump motor |

N=7.5Kw(three groups) |

|

Hydraulic pump motor |

1.5kW, n=1440r/min |

|

Cooling system rated pressure |

2.5MPa |

|

Cooling system flow |

200L/min, 200L/min, 200L/min |

|

CNC system |

SIEMENS808 |

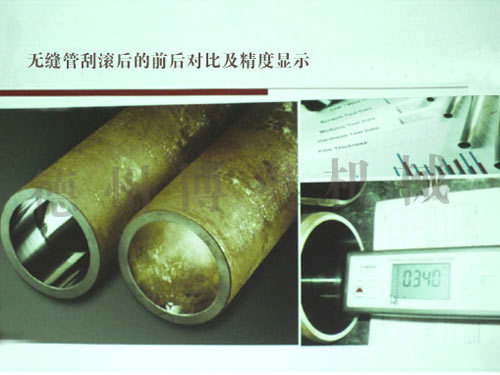

Schematic diagram of the scraping and rolling process of seamless pipe:

Feedback

Related Products

DEZHOU BOAO MACHINERY CO., LTD.

Add:Jintian Entrepreneurship Center, Tianqu Industrial Park, Decheng District

Tel:86-0534-2429518

Fax:86-0534-2429918

E-mail:dzjichuang@163.com

© 2022 DEZHOU BOAO MACHINERY CO., LTD.